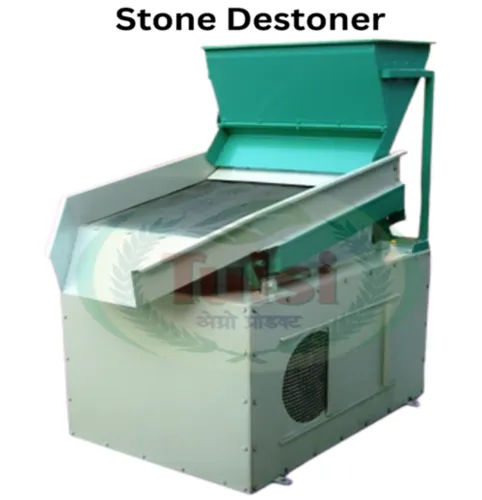

Stone Destoner

Stone Destoner Specification

- Input Power

- 2 HP

- Color

- Green & Silver

- Screen Size

- Custom (Multi-layer sieves)

- Material

- Mild Steel

- Frequency (MHz)

- 50 Hz

- Sound Level

- Low noise operation

- Voltage

- 220-240 V

- Dimension (L*W*H)

- 1600 x 900 x 1500 mm

- Weight (kg)

- Approx. 300 kg

- Product Type

- Stone Destoner

- LCD Display

- Yes

About Stone Destoner

The stone destoner is an essential agricultural and food processing machine designed to efficiently remove stones, dirt, and other heavy impurities from grains, pulses, and seeds. With advanced airflow and vibration mechanisms, it separates heavier contaminants from lighter, clean produce, ensuring high purity and quality. Built with durable materials and easy-to-operate controls, this destoner optimizes the cleaning process, protecting downstream equipment and improving product safety. Ideal for rice mills, flour mills, and grain processing units, this machine supports efficient, reliable, and high-capacity operation.

Advanced Gravity & Air Suction Technology

Utilizing gravity and air suction, the Stone Destoner effectively removes stones and heavy contaminants from grains. The vibratory hopper feeder ensures even distribution, while the powerful blower and layered sieves provide precise separation. This design guarantees improved yield and cleaner outputs for commercial operations.

Versatile Multi-Grain Cleaning Solution

Designed for multiple grain types, including rice, wheat, pulses, and paddy, the machine adapts effortlessly to different cleaning requirements with its adjustable discharge port and customizable sieve layers. Its practical versatility makes it ideal for varied grain cleaning across commercial facilities.

FAQs of Stone Destoner:

Q: How does the Stone Destoner separate stones from grains?

A: The Stone Destoner utilizes a combination of gravity and air suction techniques, along with multi-layer sieves and a vibratory feeder. Grains are separated from heavier stones and impurities as they move through the machine, resulting in thoroughly cleaned outputs.Q: What grains can be processed with this Stone Destoner?

A: This machine is suitable for paddy, rice, wheat, and pulses. Its adjustable discharge port and customizable screen sizes allow efficient operation for various types of grains in commercial cleaning plants.Q: When should I use a Stone Destoner in my processing line?

A: You should incorporate the Stone Destoner at the initial stage of your grain cleaning process, right after preliminary removal of oversized objects, to eliminate stones and enhance the quality and safety of the final product.Q: Where is the best place to install the Stone Destoner?

A: The machine is floor-mounted and designed for use in commercial grain cleaning facilities, ideally positioned where the vibratory feeder and discharge ports are easily accessible for grain input and collection.Q: What is the process for operating this Stone Destoner?

A: Simply supply grain to the vibratory feeder, select the appropriate sieve and adjust the discharge port for the specific grain, then power the machine. The integrated gravity and air suction mechanism automatically separates stones from grains during operation.Q: What are the main benefits of using this Stone Destoner?

A: Using the Stone Destoner leads to higher grain purity, reduces manual labor, minimizes machinery wear further downstream, and helps maintain low noise levels for safer, more comfortable work environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Aluminum Castings Category

crusher machine

Price 3432423.0 INR / Unit

Minimum Order Quantity : 40 Units

Voltage : 440 Megaampere ( MA)

Sound Level : 56 db

Input Power : 440 VoltAmpere (VA)

Color : red

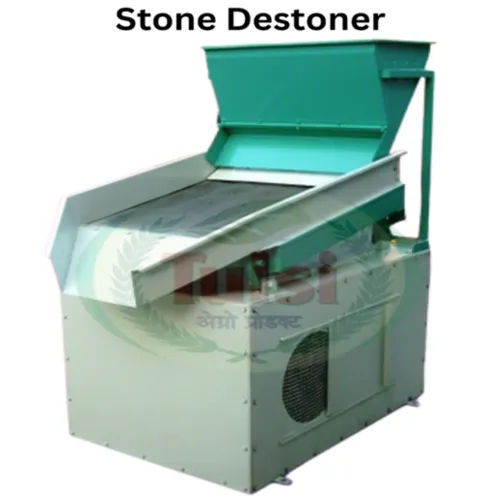

Stone Destoner123

Price 120.0 INR

Minimum Order Quantity : 10

Voltage : 220240 V

Sound Level : Low

Input Power : 2 HP

Color : Blue & White

Send Inquiry

Send Inquiry