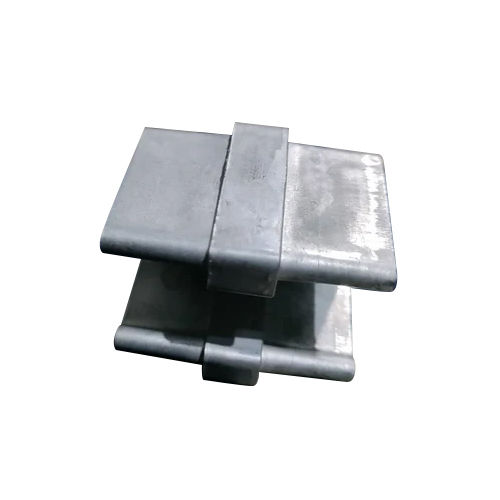

Aluminum Gravity Die Casting

Price 34433.0 INR/ Unit

Aluminum Gravity Die Casting Specification

- Color

- Silver Grey

- Screen Size

- 21-55 Inch (in)

- Material

- Plastic & Glass

- Dimension (L*W*H)

- Custom as per drawing

- Weight (kg)

- 0.5 - 15 kg

- Product Type

- Aluminum Gravity Die Casting

Aluminum Gravity Die Casting Trade Information

- Minimum Order Quantity

- 1 Nos

- Supply Ability

- 5000 Per Month

- Delivery Time

- 10 Days

About Aluminum Gravity Die Casting

Redeem the kingly advantages of our Aluminum Gravity Die Casting, crafted through an ineffable Gravity Die Casting (Permanent Mold) process. Delivering a top-tier surface finishsmooth, as cast, or machinedeach piece meets majestic 0.05 mm tolerances. The high-strength steel mold ensures regal longevity and exact customisation to your specifications. Boasting ISO 9001:2015 certification, our corrosion-resistant castings serve automotive, electrical, pump housing, and more. Machining, drilling, and tapping post-processing are available. Secure the best price and enjoy reliable monthly capacity of 2000 pieces. Distributed by Indias trusted exporter, manufacturer, and supplier network.

Aluminum Gravity Die Casting: Applications & Competitive Advantages

Our Aluminum Gravity Die Casting product is engineered for precise usage in automotive, electrical, machinery, pump housing, and general engineering applications. The majestic combination of a smooth finish, excellent corrosion resistance, and customisability ensures lasting performance in rigorous environments. Our competitive advantage lies in stringent ISO 9001:2015 standards, rapid lead times, and ability to meet specific dimensional requirements. Its broad application media guarantees versatility for various sectors demanding exceptional reliability and strength.

Main Export Markets, Payment Terms & Delivery Process

We proudly exchange and drop-off our Aluminum Gravity Die Casting products to leading export markets including the Middle East, Europe, and Asia. Payment terms are flexible to suit client needs, with transparent options available. Once an order is confirmed, items are handed over within a swift 24 week window based on quantity. Our streamlined logistics ensure efficient handling and prompt deliverywhether you are importing, distributing, or wholesaling these premium castings from India.

Aluminum Gravity Die Casting: Applications & Competitive Advantages

Our Aluminum Gravity Die Casting product is engineered for precise usage in automotive, electrical, machinery, pump housing, and general engineering applications. The majestic combination of a smooth finish, excellent corrosion resistance, and customisability ensures lasting performance in rigorous environments. Our competitive advantage lies in stringent ISO 9001:2015 standards, rapid lead times, and ability to meet specific dimensional requirements. Its broad application media guarantees versatility for various sectors demanding exceptional reliability and strength.

Main Export Markets, Payment Terms & Delivery Process

We proudly exchange and drop-off our Aluminum Gravity Die Casting products to leading export markets including the Middle East, Europe, and Asia. Payment terms are flexible to suit client needs, with transparent options available. Once an order is confirmed, items are handed over within a swift 24 week window based on quantity. Our streamlined logistics ensure efficient handling and prompt deliverywhether you are importing, distributing, or wholesaling these premium castings from India.

FAQs of Aluminum Gravity Die Casting:

Q: How does the Aluminum Gravity Die Casting process deliver such high precision?

A: This process uses permanent high-strength steel molds, enabling consistent casting with a majestic tolerance accuracy of 0.05 mm, ideal for intricate automotive, electrical, and machinery applications.Q: What customization options are available for Aluminum Gravity Die Casting?

A: We offer ineffable customization possibilities in terms of mold shape, surface finish, weight (0.515 kg), and dimensions (as per your drawings), ensuring your specific application and industry standards are met.Q: When can I expect my order to be handed over after purchase?

A: Our standard lead time is 24 weeks, depending on the order quantity. Each batch is meticulously prepared and handed over for shipping or drop-off to ensure timely delivery.Q: Where are the main regions this product is exported to?

A: We export primarily to the Middle East, Europe, and Asia, where our top-quality gravity die castings are highly regarded for their kingly reliability in diverse industrial sectors.Q: What are the benefits of choosing your Aluminum Gravity Die Casting services?

A: You redeem superior corrosion resistance, best price, ISO 9001:2015 certified quality, and a majestic range of post-processing services like machining, drilling, and tapping, ensuring your components are production-ready.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Agriculture Insecticides Category

Fipronil 40 Percent Imidaclopride 40 Percent Wg Insecticides Jaiman Powder

Price 545.0 INR / Unit

Minimum Order Quantity : 1 Piece

Screen Size : 2155 Inch (in)

Material : Plastic & Glass

Send Inquiry

Send Inquiry